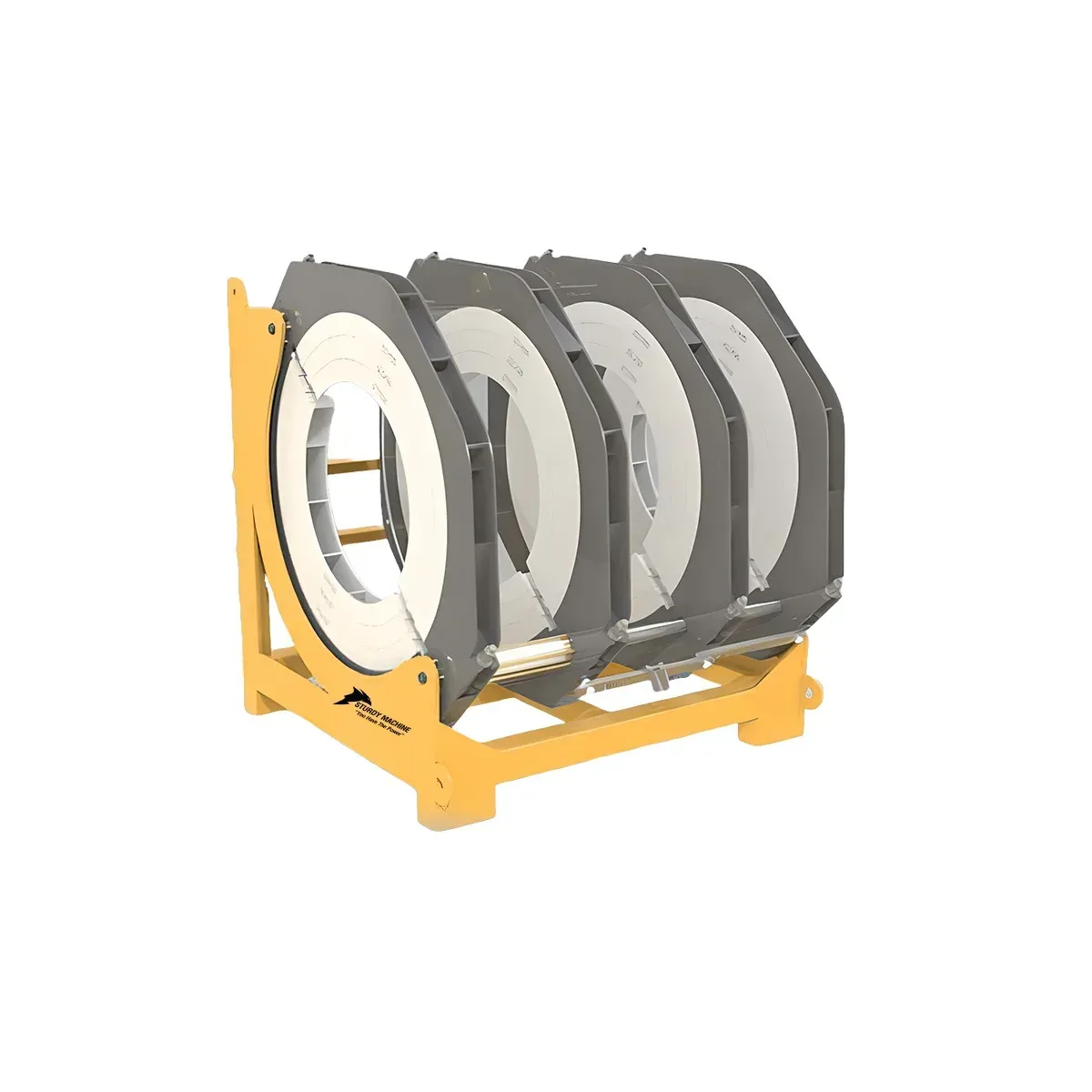

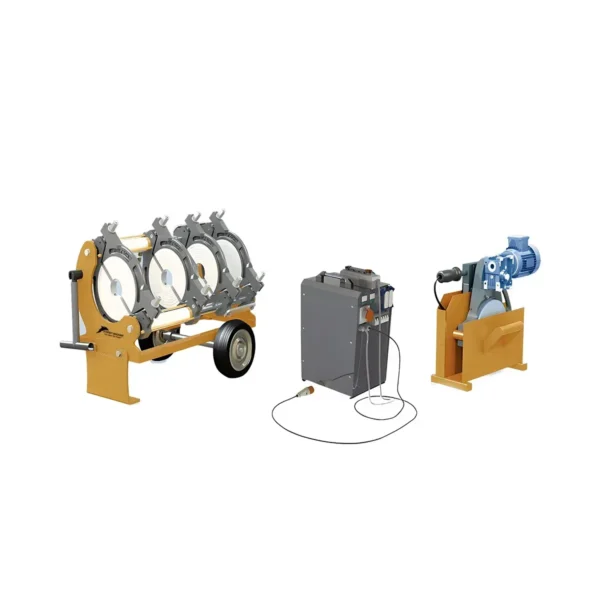

SM1600 Butt Welding Machine Body

The main body supports the plastic pipes to be welded with two movable and two fixed clamps on it, ensuring their fixation and centering.

Hydraulic pressure force is applied to the system. With two pistons on the carrier shaft, this force drives the moving clamps forward and backward, providing the movement required for the welding process to take place.

SM1600 Butt Welding Machine Trimmer

It is the butt welding machine element that performs the butt cleaning of the pipes fixed and centered on the main body with two rotating blades on the right and left sides and the cutting blades on these blades before the heating process and makes them ready for heating.

The rotary movement of the trimmer is provided by the motor and reducer group.

The trimming unit of the SM1600 Butt Welding Machine creates burr-free and parallel tube surfaces.

SM1600 Butt Welding Machine Heater

It is the butt welding machine element that prepares the pipe butt surfaces, which are brought to the desired roughness with the trimming process, for the joining process by heating them with the heating plate.

The temperature setting of the heater is made by the digital temperature adjustment thermostat on the heater plate.

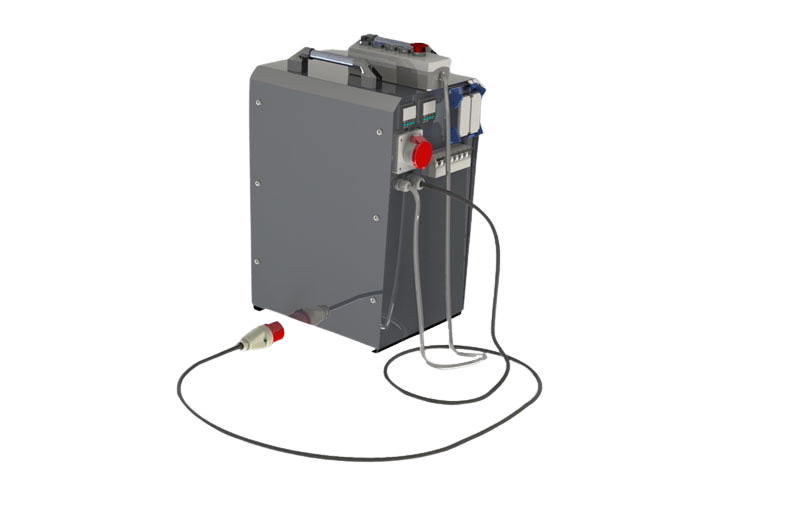

SM1600 Butt Welding Machine Hydraulic and Electrical Control Unit

The electrical and hydraulic control unit transmits the electricity required for the operation of the machine to the heater and trimmer and the hydraulic pressure to the main machine.

The control unit is operated by hand control. There are four buttons and a switch on the hand control. Buttons move the movable clamps forward and backward. The switch turns on the trimmer.

SM1600 Butt Welding Machine Enclosure Box

The casing and support box prevents the heater from losing heat and the trimmer protects the heater against external influences (impact, water, etc.) by supporting it.